A staple on almost any construction site, is the mobile elevating work platform (MEWP), commonly referred to as a ‘cherry picker’.

Often multiple MEWPs are required on a site for a variety of access requirements. Typically, large telescopic boom lifts are used around a site and to provide access to elevations and roofs externally. Whilst internally, scissor lifts give access to the underside of the roof and support structure and can be manoeuvred in tight spaces.

For manual labour tasks, these platforms are invaluable! They provide reliable, safe and flexible access at height to enable construction works – activities requiring dexterity far beyond what any drone can deliver. In an upcoming article, we will explore the concept of 3D printed construction and the role drones will have to play. But as of today, and the next decade at least it would seem, construction remains a very skilled manual process. Therefore, MEWPs will continue to play an integral role on the construction site for some time to come.

But what if you’re not carrying out manual labour, you’re instead tasked with inspecting the quality of works undertaken?

There is a strong and valid argument that gaining physical access to the structure in order to carry out a tangible inspection. Whether for construction quality inspection or building / structural inspection in general, being able to get hands on with your subject, poke and prod to check the integrity is certainly another activity which cannot be replaced by a drone (yet!).

However, this activity can be very time consuming and costly as it involves a skilled surveyor spending hours, if not days, of their time being hoisted up, down and around site in a basket. Ultimately, to capture visual data to include in quality assurance (QA) reports.

COVID Safe Construction Sites

With construction continuing throughout lockdown, but with major emphasis on safe site working and contractors streamlining their on site workforce – how can these quality checks be carried out safely?

Often a surveyor will need to be accompanied by the site or project manager so that snagging can be communicated and resolved immediately. This does however, pose a contagion risk those staff, especially if that surveyor/inspector is carrying our QA checks across multiple sites.

So, is there a more efficient, safer way of quality checking construction works?

Yes…

QA checks can now be carried out completely remotely. At Nationwide Drones, we have developed a service package specific to construction QA and communication.

Utilising the latest inspection drones and more importantly, RGB sensors technology. Combined with live remote streaming direct from the drone to your site/home office or mobile device. QA inspections can be done whilst adhering to COVID construction guidelines, keeping staff safe whilst significantly improving efficiency and as a result, reducing costs!

Drone mounted high resolution cameras capturing images up to 100MP (such as the Phase One iXM-100) allow high level inspection to be carried out quickly. You can zoom into these images retrospectively to reveal amazing detail.

Other sensors such as the Zenmuse Z30 or the H20 allow incredible detail to be captured from a safe distance.

But it’s not just the external envelope, micro drones and confined spaces drones provide the perfect tool for inspecting roof structures internally. With collision avoidance, roll cages and 180° vertical cameras no detail is inaccessible.

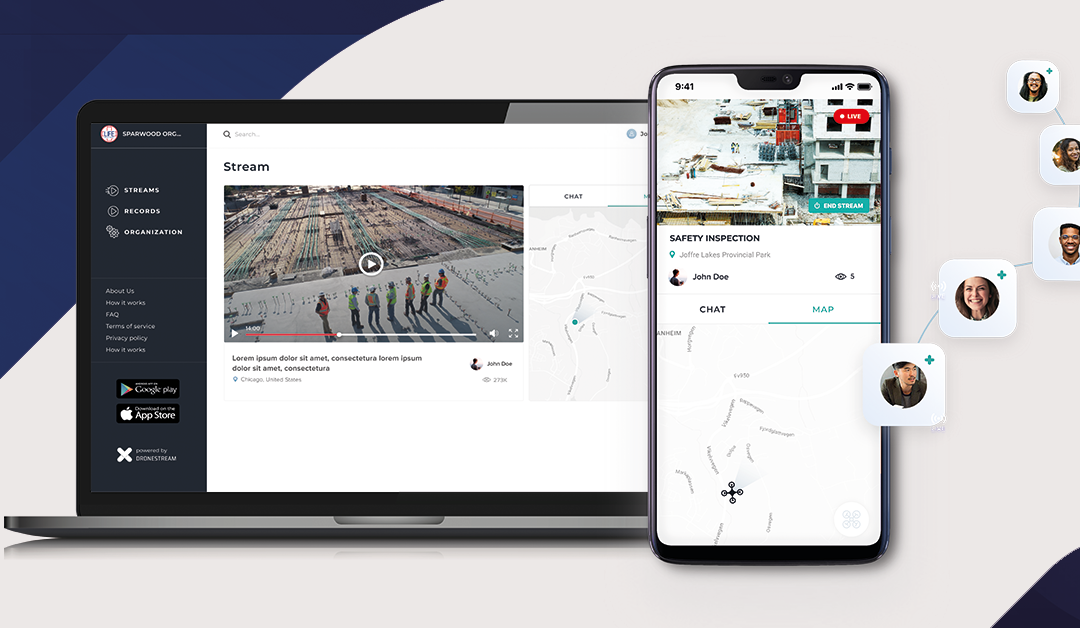

As we explored in an earlier article ‘site visits from home’ the live feed from the sensor can be streamed to all surveyors working from home and the site managers at their site office desk simultaneously. Enabling that same instant decision making process to continue without having to get in a basket!

Visual evidence can be tagged in reference to the project BIM for documentation and issue tracking. As well as embedded within site tours which we explore further in an upcoming article on the Dawn of the Digital Surveyor.

But what about the need to poke and prod?!

As already alluded to, drones can’t replace a tangible integrity inspection, but they can definitely target specific areas where this approach is required. Saving significant amounts of time and cost looking for these snagging issues. By remotely inspecting the areas which need a physical inspection, a surveyors time on site is significantly reduced, which reduces contagion risk whilst also increasing their productivity.

Our Blog

Understanding Operations Safety Case (OSC)

Understanding the Drone Operations Safety Case (OSC) and Standard Permissions Under PDRA01As drone technology rapidly evolves, businesses are...

Unleashing Speed and Efficiency through Cloud Processing

Cloud Processing In today’s digital age, the volume of data generated by various industries is growing exponentially, and the field of surveying is...

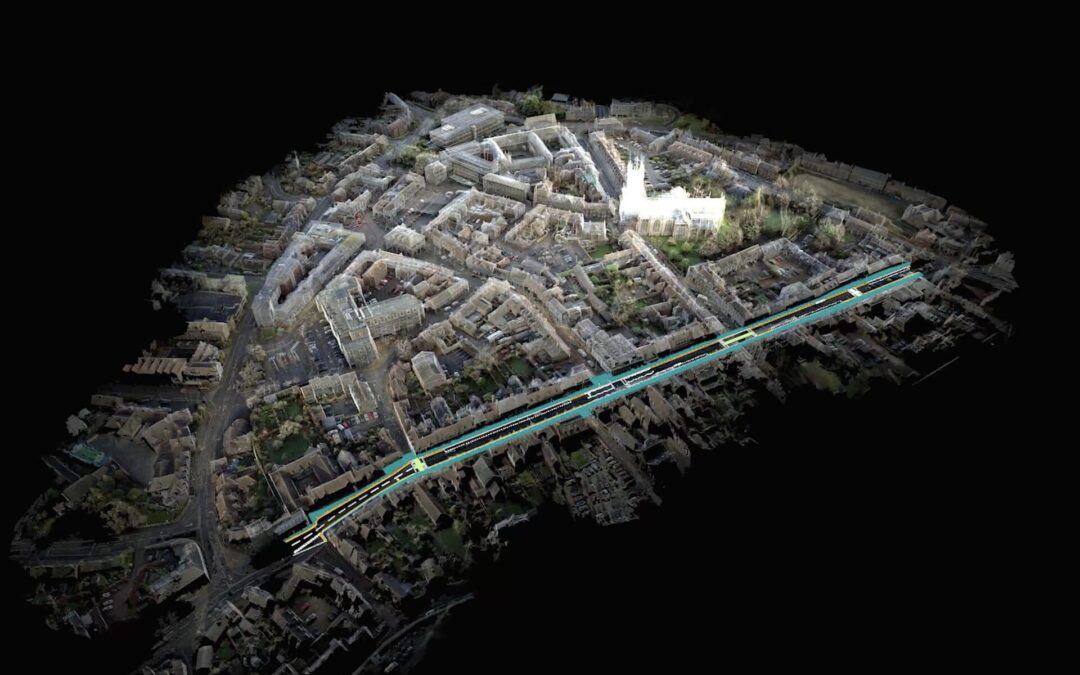

Point Clouds 101: Understanding the Digital 3D World

Point Clouds Explained Welcome to the fascinating world of Point Clouds! In this blog post, we will take you on a journey through the basics of...

The Evolution of Surveying: How Drones are Reshaping the Industry

Traditional vs ModernSurveying is a fundamental aspect of many industries, providing crucial data for planning, design, and construction projects....

Dawn of the digital surveyor – site visits from home

With the Government travel restrictions remaining in place for the foreseeable future, both domestic and international, site visits have become a...

Drones keep construction on track during lockdown

With the nation in another lockdown but construction allowed to continue, it poses a dilemma for many developers, contractors and consultants who...

Owen Jenkins

Owen Jenkins Danny Mckeown

Danny Mckeown